RV slideout rooms have become essential for modern RV living, offering additional space that turns a compact vehicle into a more livable, home-like environment. Whether parked at a campsite for an extended stay or just stopping for a quick rest, slideouts enhance comfort significantly. But with that extra space comes responsibility—proper RV slideout maintenance is critical to ensure smooth operation, avoid breakdowns, and extend the system’s life.

Without routine care, minor issues like misaligned tracks or dried seals can turn into expensive, time-consuming repairs. Slideouts can also have many potential problems, from hydraulic leaks to electric motor failures. This guide will cover everything you need to know about RV slideout maintenance and repair, complete with practical advice, step-by-step procedures, and recommended products. When you’re done reading, you’ll have the confidence and knowledge to keep your slideout performing at its best.

Periodic Preventative RV Slideout Maintenance

Lubrication and Greasing

One of the most crucial RV slideout maintenance tasks is lubrication. Over time, the mechanical components that allow the slideout to extend and retract will wear down due to friction. Electric slideouts depend on a series of gears and tracks, while hydraulic slideouts rely on arms and joints to move smoothly. Regular lubrication prevents these components from grinding and seizing up, which could lead to significant mechanical failure.

- Procedure:

The rails, gears, and tracks are the most common parts that need lubrication. For electric slideouts, focus on the gear track and mechanical joints. For hydraulic systems, check the arms and pivot points. Use a silicone-based or dry lube spray designed specifically for RV slideouts to ensure it won’t attract dirt or grime. Apply the lubricant while the slideout is fully extended, ensuring you coat all moving parts evenly. Wipe away any excess lubricant to avoid buildup.

For hydraulic systems, you’ll also want to inspect the hydraulic arms for any signs of wear. If they appear corroded or dirty, clean them before applying lubricant.

- Recommended Products:

- Camco Slide-Out Lube: This silicone-based lube is a favorite among RV owners because it doesn’t attract dust or debris. It’s also safe for rubber and metal components, making it ideal for slideouts.

- Thetford Premium Slide-Out Lubricant: This lubricant, known for its long-lasting formula, protects slideouts from wear and rust. It’s especially useful in areas exposed to rain or humidity.

Depending on usage, regular lubrication should be done every 3-6 months. If your RV sees heavy use, consider increasing the frequency of this RV slideout maintenance task. Without lubrication, the slideout system could experience mechanical failure, leading to more costly repairs.

Seals and Gaskets Maintenance

While focusing on the moving parts of your slideout is easy, don’t forget about the seals and gaskets. These rubber components keep water, dirt, and debris from entering your RV. Over time, seals can dry out, crack, or lose their elasticity, allowing moisture to seep into your RV. This can lead to water damage, mold, and many other problems.

- Procedure:

Regularly inspect your slideout seals and gaskets. Use a rubber seal conditioner to keep the seals flexible and prevent them from drying out. Every 3-4 months, clean the seals with mild soap and water to remove any accumulated dirt. After cleaning, apply a UV protectant to shield them from sun damage. If you notice any cracks or gaps, replace the seals immediately to prevent leaks.

When replacing seals, get the exact size and type recommended by the RV manufacturer. Applying too much conditioner can also cause the seals to become too soft, so always follow the product instructions.

- Recommended Products:

- 3-IN-ONE RVcare Rubber Seal Conditioner: This conditioner keeps slideout seals pliable, reducing the risk of cracks and leaks. It also protects against UV damage.

- Dicor Seal-Tite RV Seal Conditioning Treatment: This is another excellent option for protecting and conditioning slideout seals. It’s specially formulated for RV applications and provides excellent UV protection.

Without proper seal maintenance, you risk significant water damage inside your RV. Even a tiny leak can cause wood rot, mold growth, and structural damage over time.

Inspecting the Slideout Awning

Slideout awnings are a common feature in RVs, protecting from weather and debris. However, awnings are often overlooked during routine RV slideout maintenance, even though they are essential in protecting the slideout system from damage.

- Procedure:

Inspect the awning fabric for tears, sagging, or dirt accumulation. Clean the awning at least once every six months using a mild soap and water solution. A specialized cleaner may be required for heavily soiled awnings. After cleaning, apply a fabric protectant to shield it from UV damage and help it resist mildew and stains.

Ensure that the awning retracts and extends smoothly. If the awning starts to sag, it could collect water, leading to mildew or mold. You’ll also want to check the hardware and springs for signs of rust or wear. Tighten any loose screws or bolts, and replace any parts showing signs of damage.

- Recommended Products:

- 303 Fabric Guard: This fabric protectant is ideal for RV awnings. It repels water, dust, and UV rays and helps maintain the awning’s flexibility.

- Camco Awning Cleaner: A specially formulated cleaner that removes dirt, mildew, and stains from RV awnings without damaging the fabric.

Neglecting your slideout awning can lead to more severe issues down the road. Without an effective awning, your slideout is more exposed to rain, debris, and sun damage, which can lead to costly repairs.

Checking the Alignment

If your slideout is not aligned correctly, it may stress the motor, gears, or hydraulic system. Misaligned slideouts can also cause wear on the seals and gaskets, leading to gaps where water and air can enter your RV. This is arguably the most expensive RV slideout maintenance issue to fix, so ensure you avoid binding the slideout when bringing it in or out.

- Procedure:

To check the alignment, fully extend the slideout and inspect the gaps between the slideout and the RV. The gaps should be even on all sides. Your slideout is misaligned if one side is higher or lower than the other. You can often adjust the alignment by tightening or loosening the adjustment bolts for electric slideouts. For hydraulic slideouts, you may need to change the hydraulic arms.

If you notice significant misalignment, consult a professional. Ignoring alignment issues can lead to severe damage over time, including warped frames and damaged slideout tracks.

- Recommended Services:

- Lippert Slide-Out Alignment Kit: This kit is designed to make minor adjustments to slideout alignment, particularly for electric slideout systems.

- Professional RV Service Center: A professional service center can ensure that the slideout is appropriately aligned and functioning correctly for more severe alignment issues. Even within the RV technician community, slideout repair is a specialized discipline, so find someone skilled in this if you decide to take this route.

Hydraulic System Maintenance

Hydraulic slideouts are often used in larger RVs because they provide more power and can handle heavier loads. However, hydraulic systems also require more RV slideout maintenance than electric slideouts, particularly when it comes to hydraulic fluid and hoses.

- Procedure:

Check the hydraulic fluid levels every six months. If the fluid is low, top it off with the manufacturer-recommended fluid. Inspect the hydraulic hoses and fittings for any signs of leaks, wear, or cracks. If you notice any fluid around the hoses or pump, it’s a sign of a leak, and the damaged hose or fitting should be replaced immediately.

Consider having a professional inspect the system annually for hydraulic slideouts that see heavy use. Hydraulic components are under high pressure, and DIY repairs can be dangerous without the proper tools and knowledge.

- Recommended Products:

- Lippert Hydraulic Fluid: This fluid is designed for RV hydraulic systems, ensuring smooth operation and preventing corrosion.

- AP Products Hydraulic Hose Kit: A high-quality replacement hose kit compatible with most RV hydraulic slideouts.

Ignoring hydraulic fluid levels or leaking hoses can cause your slideout to fail, potentially leaving you stuck with a partially extended slideout and no way to retract it. Proper hydraulic RV slideout maintenance is vital to avoid costly emergency repairs.

Common RV Slideout Repairs

Even if you diligently perform regular RV slideout maintenance, you may be unlucky and have a slideout breakdown. I’ve compiled a list of the most common RV slideout repair issues:

Electrical System Repairs

Electric slideouts are convenient, but they’re not immune to issues. The motor may burn out, the wiring can become damaged, or the control system could malfunction. Electrical problems can cause the slideout to stop working entirely, leaving you stuck without the ability to retract or extend it.

- Procedure:

If your electric slideout won’t extend or retract, the first thing to check is the power supply. Ensure the RV is connected to shore power or the battery has enough charge. Next, check the wiring for any signs of damage or loose connections. Use a multimeter to check whether the motor is receiving power. You may need to replace the wiring harness if no power is detected.

If the motor has burned out, you must replace it with a compatible model. Replacing the motor can be a DIY job if you’re comfortable working with electrical components, but you may want to consult a professional if you’re unsure.

- Recommended Products:

- Lippert Slide-Out Motor: This motor is designed specifically for Lippert electric slideout systems and is one of the most popular options on the market.

- AP Products Slide-Out Motor Repair Kit: A comprehensive repair kit includes everything you need to fix common issues with electric slideout motors.

Electrical problems can be frustrating, especially when they prevent you from retracting the slideout on the road. Regular inspections and prompt repairs are essential for keeping your electric slideout in good working condition.

Hydraulic System Repairs

Hydraulic slideouts are incredibly powerful, but they also come with their own set of challenges. Hydraulic systems function on a complex network of hoses, pumps, and cylinders. If any part of the system fails, the slideout may stop working.

- Procedure:

If your hydraulic slideout is malfunctioning, the first step is to check the hydraulic fluid level. Low fluid is often a sign of a leak, so you must inspect the hoses and fittings for damage. If you identify a leaking hose, replace it with a new one that matches the system’s specifications.

Hydraulic pumps can also fail, leading to a total loss of power for the slideout. If the pump is faulty, it will need to be replaced. Replacing a hydraulic pump is more complex than replacing an electric motor and may require professional assistance.

- Recommended Products:

- Lippert Hydraulic Pump Assembly: This replacement pump is designed for Lippert hydraulic slideout systems and provides reliable performance.

- Enerpac Hydraulic Seal Kit: A high-pressure seal kit that helps repair leaks in hydraulic slideout systems, extending the life of your hydraulic components.

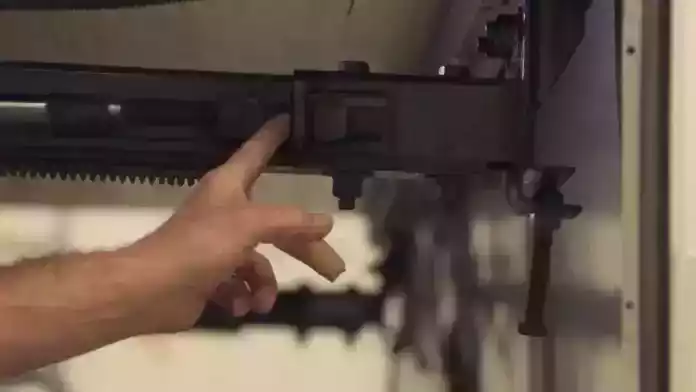

Fixing Slideout Track and Gear Problems

The track and gear system that moves the slideout in and out can wear down over time. If the gears are worn or damaged, the slideout may struggle to extend, retract smoothly, or become stuck.

- Procedure:

Start by inspecting the gear mechanism and slide tracks. Look for any signs of wear, rust, or misalignment. If the gears appear worn, they’ll need to be replaced. For track issues, ensure that the track is free of debris and properly aligned. You may need to adjust the position of the slideout to ensure it moves along the track smoothly.

In some cases, you may need to replace the entire track assembly. This repair is more involved, but a handy RV owner can do it with the right tools.

- Recommended Products:

- Kwikee Gear Pack for Slide-Outs: A popular replacement gear kit with many standard slideout systems.

- Lippert Slide-Out Track Repair Kit: This kit includes everything you need to fix common track and alignment issues with Lippert slideout systems.

Dealing with Water Leaks

Water leaks around slideouts can cause extensive damage if left unaddressed. These leaks are often caused by damaged or dried-out seals but can also occur due to poor alignment or cracked gaskets.

- Procedure:

Begin by inspecting the seals and gaskets around the slideout for any visible signs of damage. If the seals are cracked, replace them immediately. For small gaps, use an RV-grade caulk to seal the area and prevent further water intrusion.

If the leak is severe, you may need to remove the slideout and inspect the frame for damage. Water can seep into the frame and cause wood rot, mold, or mildew. In these cases, it’s best to consult a professional to assess the extent of the damage.

- Recommended Products:

- EternaBond RV Sealant Tape: This versatile sealant tape is perfect for quick fixes and long-term sealing of leaks around slideouts.

- Dicor Lap Sealant: A flexible, durable caulk ideal for sealing gaps in the RV’s exterior, especially around slideouts.

Repairing Slideout Floor Damage

The floor is one of the less obvious areas of damage in RV slideouts. Over time, moisture can seep into the floor under the slideout, leading to warping or rot. This is particularly common in older RVs where the seals have degraded.

- Procedure:

If you notice soft spots, warping, or sagging in the slideout floor, it’s essential to address the issue quickly. Start by removing the damaged flooring. Check the subfloor for moisture or rot. If the subfloor is compromised, it will also need to be replaced. Once the area is dry and repaired, install new flooring and add a moisture barrier to prevent future issues. - Recommended Products:

- AP Products Slideout Floor Replacement Kit: A comprehensive kit replaces damaged flooring in RV slideouts.

- Titebond Moisture Barrier: A waterproof adhesive that protects against future water damage to your slideout floor.

Best Operating Procedures to Prevent Premature Slideout Failure

Extending and Retracting Slideouts Properly

Operating your slideout correctly is critical to preventing unnecessary wear and tear. Many RV owners don’t realize that improper slideout use can cause significant damage over time.

- Procedure:

Before extending or retracting your slideout, make sure the RV is level. Uneven ground can put additional strain on the slideout’s mechanical components. Also, avoid storing heavy items on or near the slideout, which can cause sagging or misalignment. When extending the slideout, ensure it’s free of any obstructions that could cause the gears to jam.

Always retract the slideout fully before moving the RV. Leaving it partially extended can damage the gears, track, or hydraulic system during travel.

Inspecting Before Use

Inspecting your RV slideout before hitting the road is always a good idea. Regular inspections can help catch potential issues before they become costly repairs.

- Procedure:

Start by inspecting the seals and gaskets for any signs of wear or damage. Check the gears, track, and hydraulic arms for any signs of rust or misalignment. Use a multi-tool to tighten any loose bolts or screws, and inspect the motor and hydraulic pump for unusual sounds.

If you notice anything unusual, address the issue before using the slideout. Ignoring minor problems can lead to more significant issues later on.

Weight Distribution Awareness

One often overlooked factor in RV slideout maintenance is the role of weight distribution. If your RV is not correctly balanced, it can put undue stress on the slideout system, leading to premature failure.

- Procedure:

Make sure your RV is loaded evenly, with heavy items distributed throughout. Avoid placing heavy items on or near the slideout, as this can cause the slideout to sag or misalign over time. Regularly check the weight distribution and adjust as necessary. - Recommended Tools:

- Weight Distribution Hitches: These hitches help ensure even weight distribution across your RV, reducing the strain on the slideout system.

- Leveling Blocks: Use leveling blocks to properly level your RV before operating the slideout.

Monitoring for Unusual Sounds or Movements

When using your slideout, pay attention to any unusual sounds or movements. Grinding, squeaking, or jerky movements are often early indicators of mechanical problems.

- Procedure:

Stop using the slideout and inspect the system if you notice any of these signs. Look for signs of wear or damage in the gears, track, or hydraulic arms. Early detection and repair can prevent more serious issues from developing.

Expert Tips for Maintaining RV Slideouts

As an RV parts expert, I recommend making preventative RV slideout maintenance a regular part of your RV care routine. Hydraulic systems, particularly, require more frequent checks due to their complexity and potential for fluid leaks. Regularly inspect seals, lubricate moving parts, and check alignment to prevent major issues from developing. Taking the time to perform these small tasks every few months will save you time, money, and headaches in the long run.

When choosing products for your slideout, always go for quality. Cheap lubricants or sealants might save you a few bucks in the short term but often lead to more significant problems later. Invest in trusted brands and manufacturer-recommended products to ensure your slideout stays in top condition.

Summary

RV slideout maintenance doesn’t have to be difficult, but it requires consistent care and attention. From lubrication and seal maintenance to hydraulic system inspections and electrical repairs, regular RV slideout maintenance can prevent costly breakdowns and extend the life of your RV. Following these guidelines and using the recommended products can keep your slideout functioning smoothly for years.

Whether you’re a seasoned RV owner or a newbie, keeping up with your RV slideout maintenance will save you from the frustration of unexpected repairs and give you more time to enjoy the open road. Stay proactive, perform regular checks, and your RV slideout will reward you with reliable performance on all your adventures.